We make 2 mowers - within a minute!

We make 2 mowers - within a minute!

The assembly line for complete assembled robotic lawnmowers was a challenge for Krofian not only in terms of the technical aspect of completing the technology, but also in the way of conceptualizing its solution.

As the share of automation and robotization in households increases, the demand in the consumer industry sector increases. This is good for our company in terms of the targeted diversification of the industry and the shift of the major customers for automation outside the automotive sector as well.

The principle of a robotic lawnmower is not the same as that of a gasoline or electric lawnmower. The difference is in the robot's autonomy, when it goes out on its mission several times a day, completely independent of the "gardener's" time. In this way, it cuts the grass in millimetres. The fine grit is then left to lie in the lawn, where it spontaneously and quickly absorbs and thus fertilizes the lawn.

Illustrative image of a robotic lawnmower (this is not the model that is assembled on the Krofian line)

Lawns maintained by robotic mowers then have the same appearance throughout the growing season. The drive of the mowers is, of course, electric and therefore quiet, so noise is eliminated (my neighbor is set to mow twice a day, and if I hadn't seen "Máňa" (coincidentally from the same manufacturer for whom we implement the line) driving around his garden, I wouldn't have even known that he ever cuts the grass.

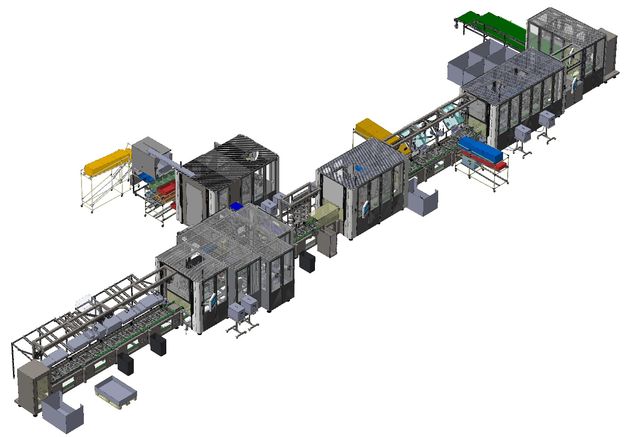

Line concept

The assembly line, which is currently nearing completion, assembles complete robotic mowers in several variants, right from the very beginning. So the whole process starts with the insertion of the basic supporting part and continues through the revival of the electrical circuits to the upload of the control software.

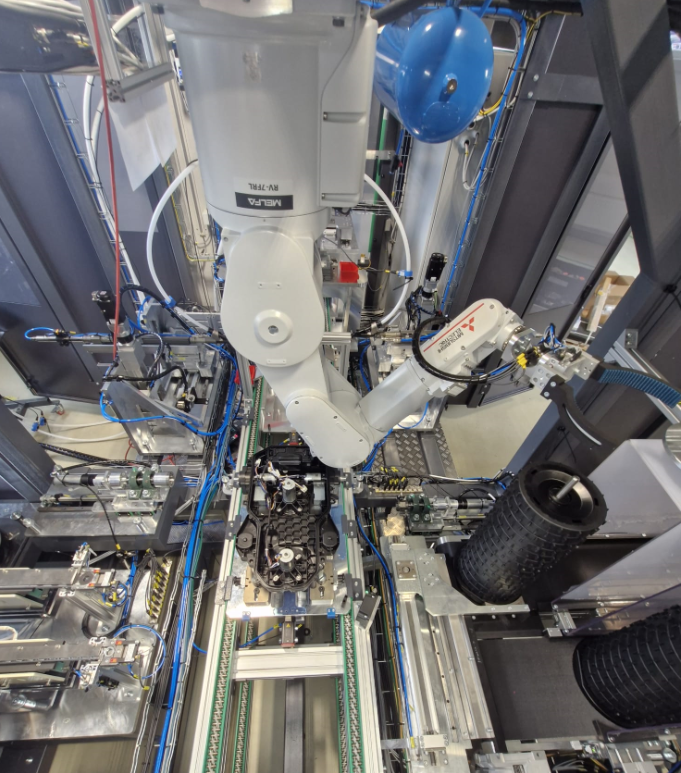

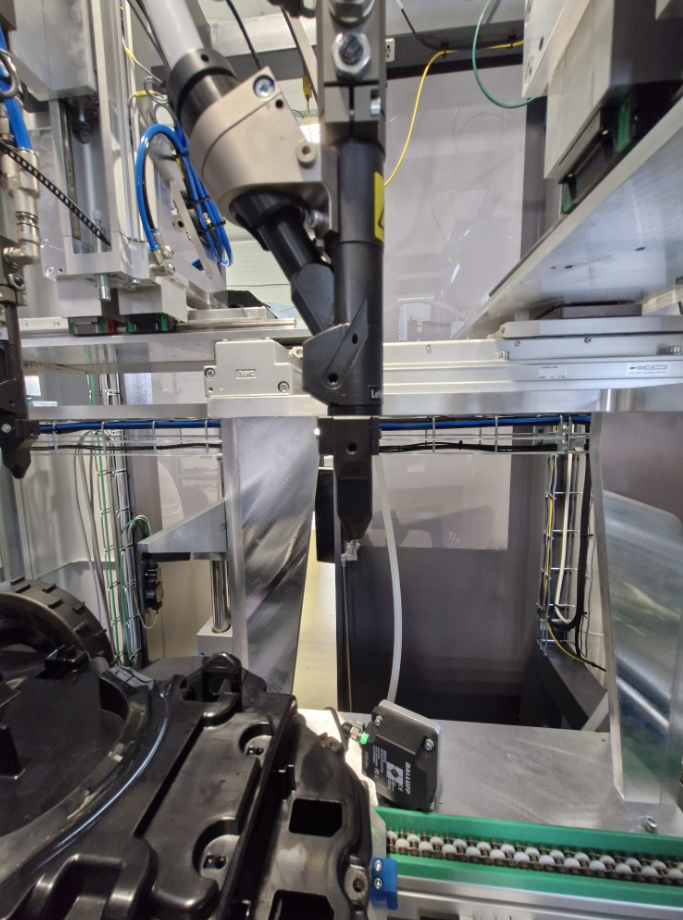

Robotic station for setting up wheels

The line is designed as a linear conveyor system, where pallets with loading preparations are carried by the mower from the base of the chassis through the assembly and inspection workplace to the output conveyor, where it leaves the line completely assembled and ready for use.

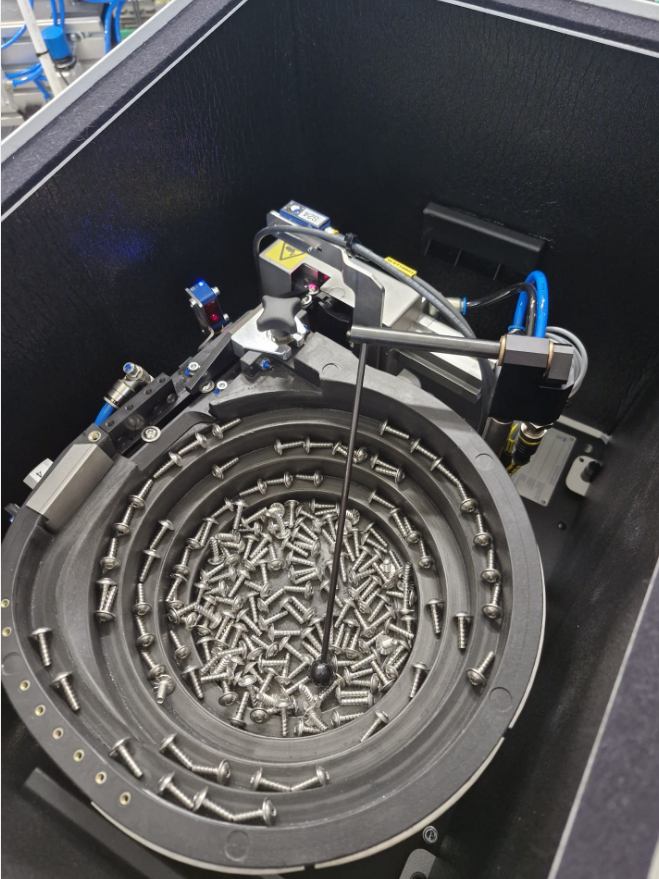

At the beginning of the process, the operator installs the basic part of the mower chassis. Up to 50 parts or their assemblies are gradually assembled on this chassis manually or automatically or with the help of a six-axis robot. All assembled components are clipped or screwed into the basic chassis. In addition to the large number of parts to complete, the interesting thing is the fact that 16 automatic screwing systems are used here, which screw up to 56 screws in one process!

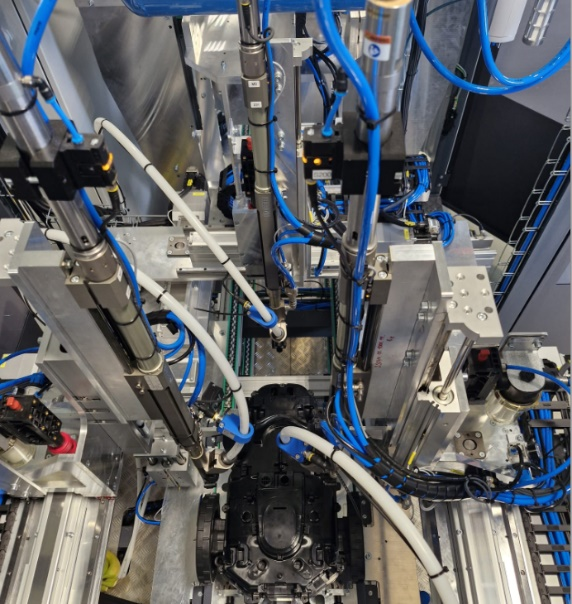

Screw spindles

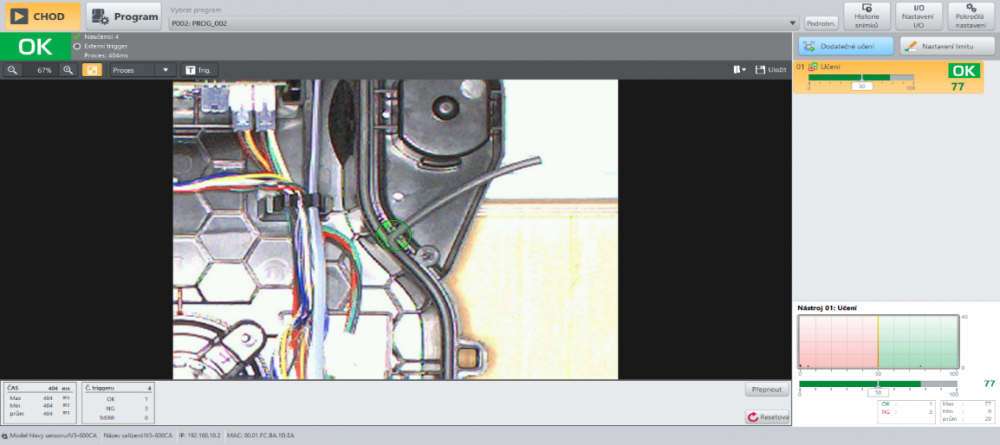

Such a number of screwing systems used on one line is a record for our company. During assembly, of course, the correctness and installation of all components, which the given version of the mower should contain, is checked. For that reason, the line is equipped with 9 camera controls and countless sensory controls.

View of detection using a camera sensor

The brain of the whole product

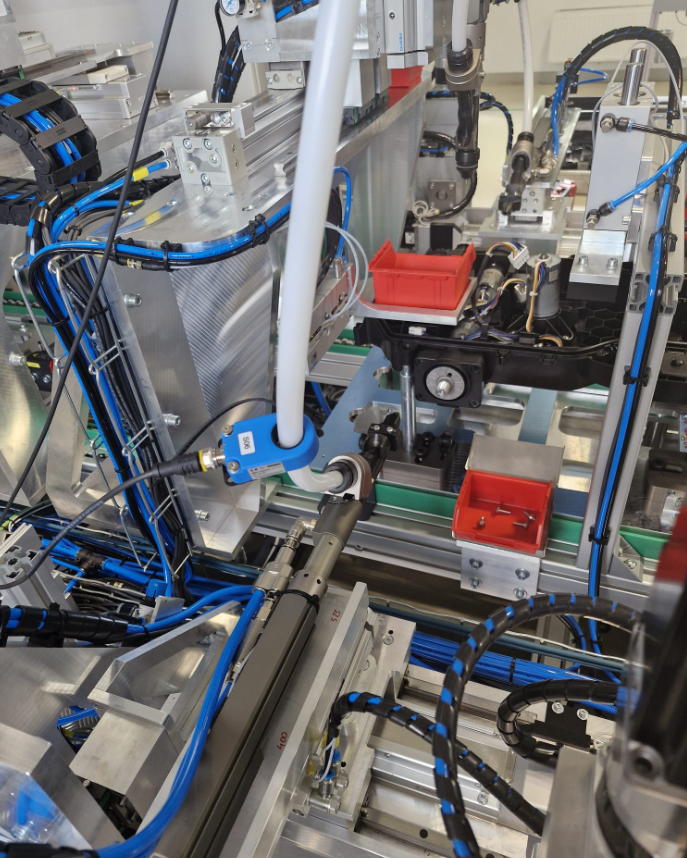

During assembly, fitted surface plates are inserted, which are the control and brain of the entire mower. Of course, all these electronic components are susceptible to electrostatic discharge, therefore the line is designed so that all electrostatic charge is conducted and grounded and thus does not damage susceptible electronic components.

In the vortex of the completion process

The installation of components is not only from one side, but from all sides. It is necessary to fit the main drive wheels from both sides of the mower, the mowing discs are fitted from the bottom and at the end of the process the protective cover is fitted from the top. In practice, this means that when passing through the assembly line, the mower turns around all its axes back and forth.

In order for all these processes to take place in a cycle time of 30 seconds, it was necessary to equip the line with 23 assembly stations. This has grown the technology to a respectable 30 meters in length.

It is a beautiful sight when you set up the first part at the beginning of the line and after about 12 minutes a fully assembled robotic lawnmower comes out at the end, ready to be packed and distributed to customers.

It is once again a great achievement by our entire team at Krofian and this line shows that it is not only in the automotive industry that it is possible to go with the era of ubiquitous robotization. Our company can be proud to contribute to the spread of robotics among consumers.

Stanislav Koutný, Construction Manager

Gloss of the author of the article:

Although I am a fan of technological improvements and the expansion of robotics into households, the use of a robotic lawnmower on my property around the house is not possible due to the slope of the larger part of the property, which is approximately 45°.

That's why I bought a more traditional mower this year. It can handle this slope and also automatically fertilizes the lawn - sometimes too much.