We save 5 million per year!

We save 5 million per year!

On the line - an injection press for the production of plastic parts - there are 2 operators for inspection and assembly. It is a highly used technology, so the operation is continuous, in three shifts (i.e. at least 6 operators). One operator costs the company approximately CZK 50,000 per month (charges and overhead). All together, it is min. CZK 300,000 per month. Annual expenses will then increase to CZK 5,000,000.

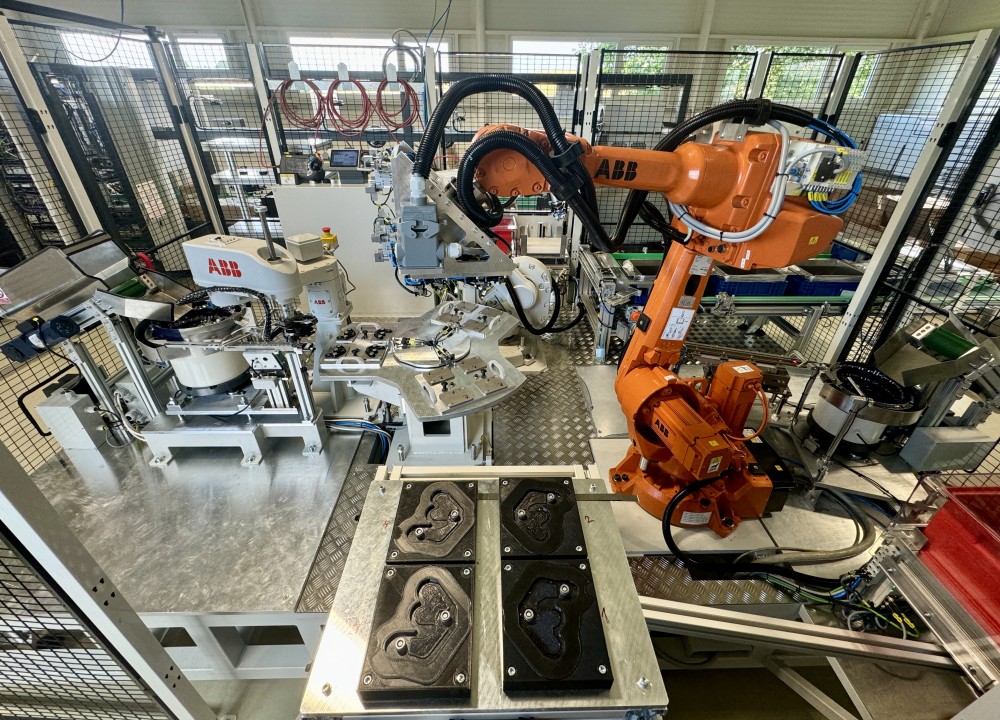

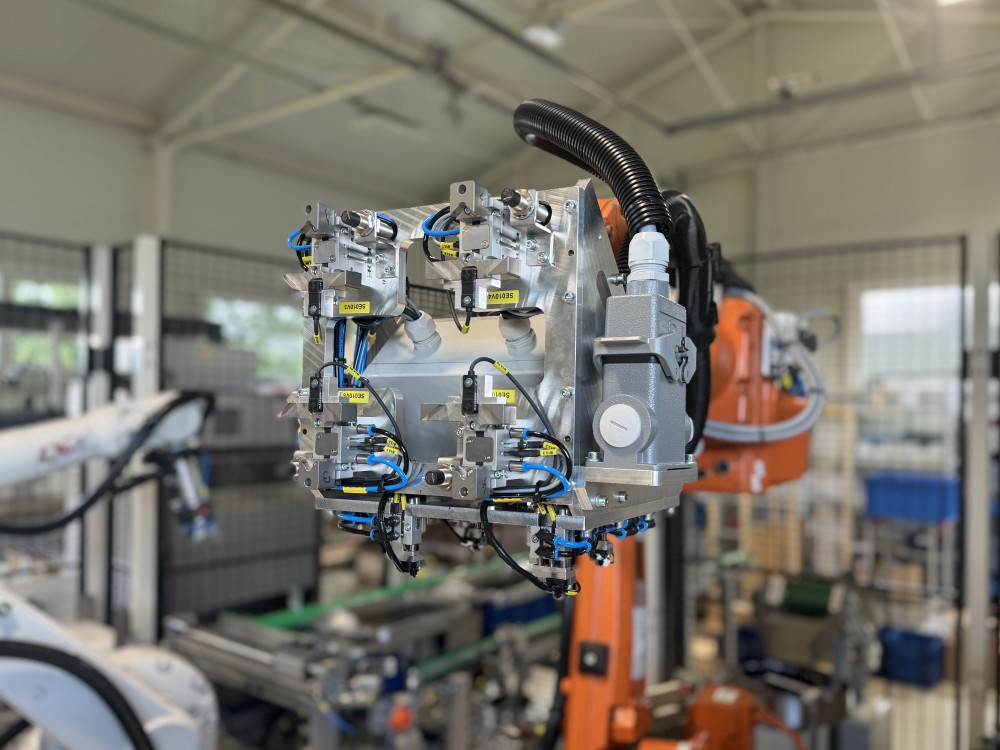

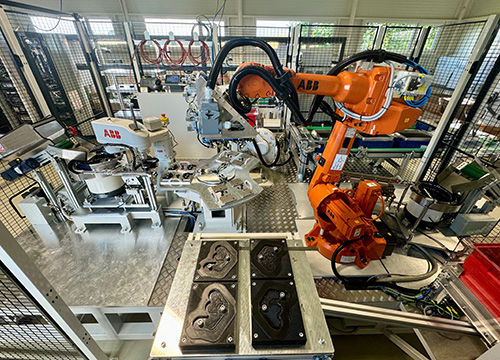

With our solution, we will replace service and additional processes, represented by human power, with robots. He knows how to assemble cases, screws, pressing, marking, visual inspection up to final packaging. They are not sick, they are not absent, they work continuously.

In addition, in the event of a change in production, thanks to exchangeable beds for products and universal robots, the machine can be easily converted to another product.

Our last project was about the expansion of injection presses with modules that will replace the service processes. The production of plastic parts is specific in its speed (our current project 9.5s / part) and the necessity to produce 24/7 (or change tools).

The machine has compact dimensions and fits easily in the aisles between the machines. The function of the press is simulated on our assembly (preparation and communication interface) and after delivery to the customer we revive and install it in a short time.