Workshop tradition continues: Part 2 of automated line assembly

Workshop tradition continues: Part 2 of automated line assembly

After the successful first part of the workshop, we welcomed third-year students of the Mechanical Engineering and Metalworking programs. They faced a full-day program dedicated to assembling an automated production line – the second chapter of their adventure with modern technology.

Theory that comes alive

The day began with a session led by designer Jan Martínek and development and design manager Stanislav Koutný. Students delved into the backstage of designing and developing production lines – from the first sketches to simulations of work movements. The presentation was based on real projects, so it was theory with a clear purpose: to show how an idea turns into a functioning machine.

Key moments were analyzed:

- the role of the project team and its cycle

- design of individual stations

- technical drawings and specifications

- simulations of work movements

- basics of adjustment, maintenance, and troubleshooting

When the line starts running

After a short break, students moved directly into practice. Assembly leader Jaroslav Cerha guided them through the lines currently being assembled. Theory instantly transformed into reality – metal structures, moving parts, and real processes they could experience hands-on.

Conclusion

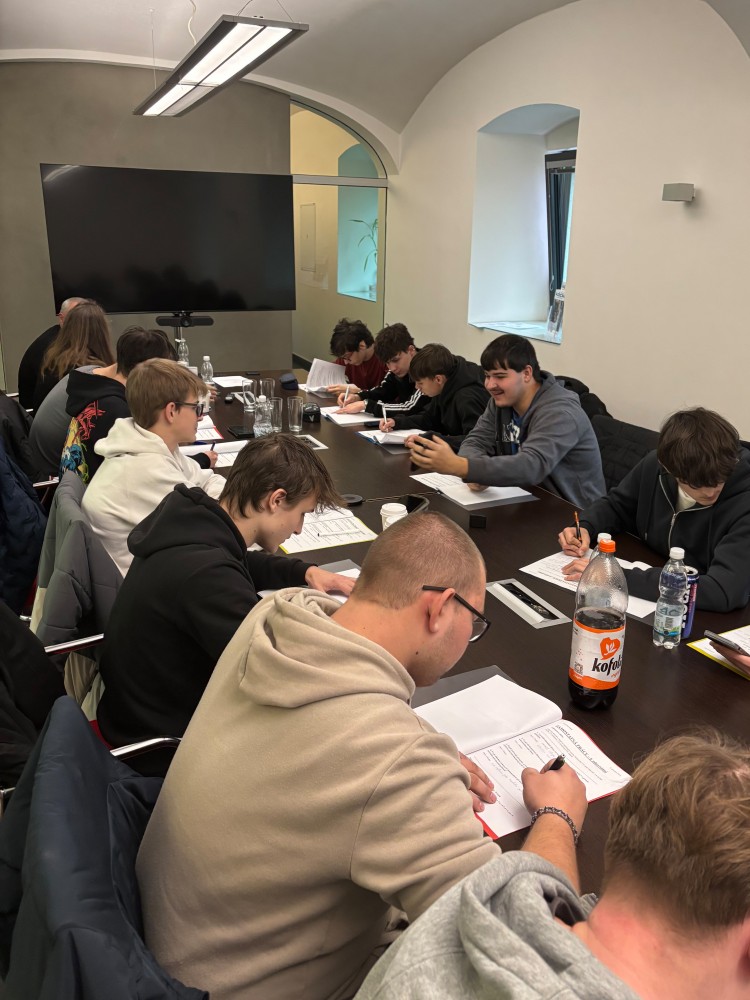

At the end of the day, students took a short test to verify what they had learned from the workshop. They summarized the benefits simply: new information, experiences, knowledge for life and future work. The second part of the workshop cycle once again demonstrated that practical experience is irreplaceable.